PRODUCTS

Products - Eco-Technical secondary frame

WE LOOK TO THE FUTURE

Looking to the future for us means finding innovative solutions with a high technological content and, at the same time, that are sensitive to environmental needs.

This is why we have created the Tecnico fastening system. This is a mechanical system that's safe and quick. Thanks to it, Tecnico ensures clients with installation, making the worksite immediately accessible and with firm costs.

The positioning of the bracket during the construction of partitions is the only cost to the company, and it prevents:

- breaking the wall to create anchoring inserts

- creating support points for the secondary frame to correctly dimension it

- production of debris and masonry rubble

- worksite clean-up when installation is complete

- elimination of microscopic cracks which are often produced in the final plaster at the anchor points.

By combining the Tecnico system with our secondary frame made of wood rather than PVC, the result is Ecotecnico.

Our PVC?secondary frame adds features of non-deformability, and exceptional hold of screws and nails. This eliminates the problems of the wood secondary frame, discovered at the moment of installation of the doors, due to alterations of quality, size, thickness, and width as a result of changes in humidity.

POSITIONING THE SECONDARY FRAME

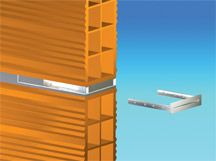

1st phase

BRACKET PLACED IN CONCRETE

The Tecnico bracket is sunken into the mortar between perforation and perforation in the construction of the wall, and flush with it.

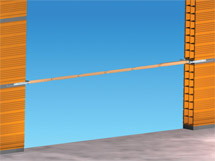

2nd phase

INSERTION OF U-BOLTS

Three U-bolts are inserted per side.

3rd phase

CLEARANCE

Adjustment of the two lower U-bolts based in the maximum clearance of the secondary frame.

4th phase

VERTICAL POSITIONING

The U-bolts are adjusted so they are perfectly vertical to one another, due to their movement when they are inserted in the bracket.

5th phase

FASTENING OF THE U-BOLTS WITH SCREWS

The U-bolts are fastened with the four side screws.

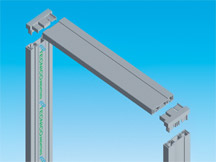

6th; phase

PRE-INSTALLATION OF SECONDARY FRAME

The pressed corners ensure a 90° angle and outstanding speed of pre-installation.

7th phase

FASTENING

The secondary frame is screwed into the U-bolts, ensuring that it is perfectly vertical and correctly dimensioned.

8th phase

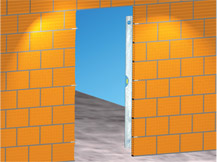

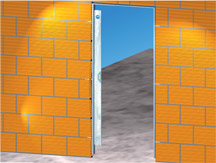

INSTALLATION

Secondary frame properly installed with the TECNICO system.

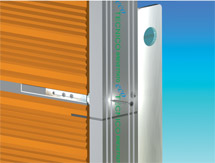

8th phase

DETAIL

Example of adaptability to any kind of wall.

Less waste, more trees!

Less waste, more trees!